What are strategies to prevent deformation in CNC Machining of POM C Plastic Items?

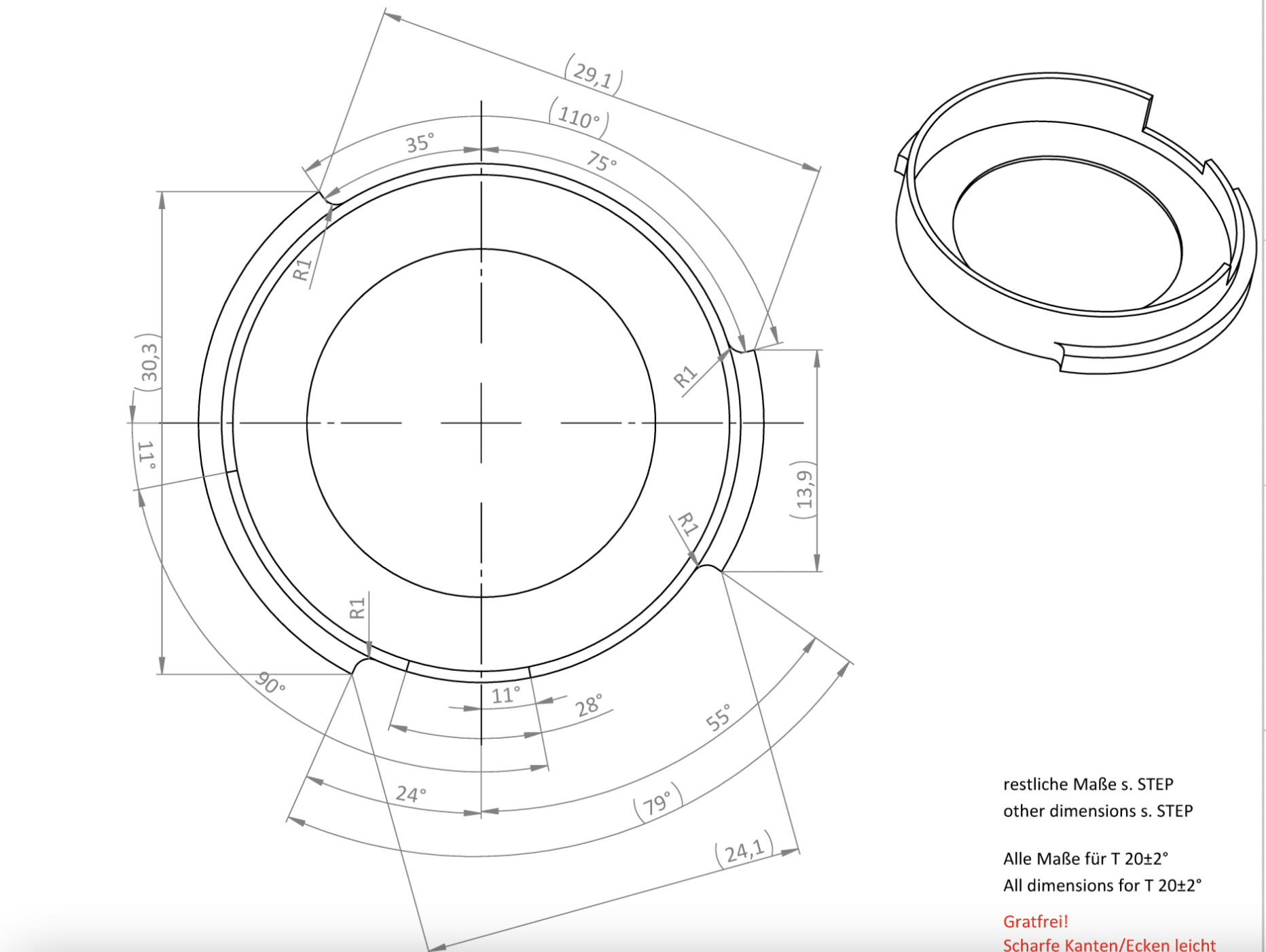

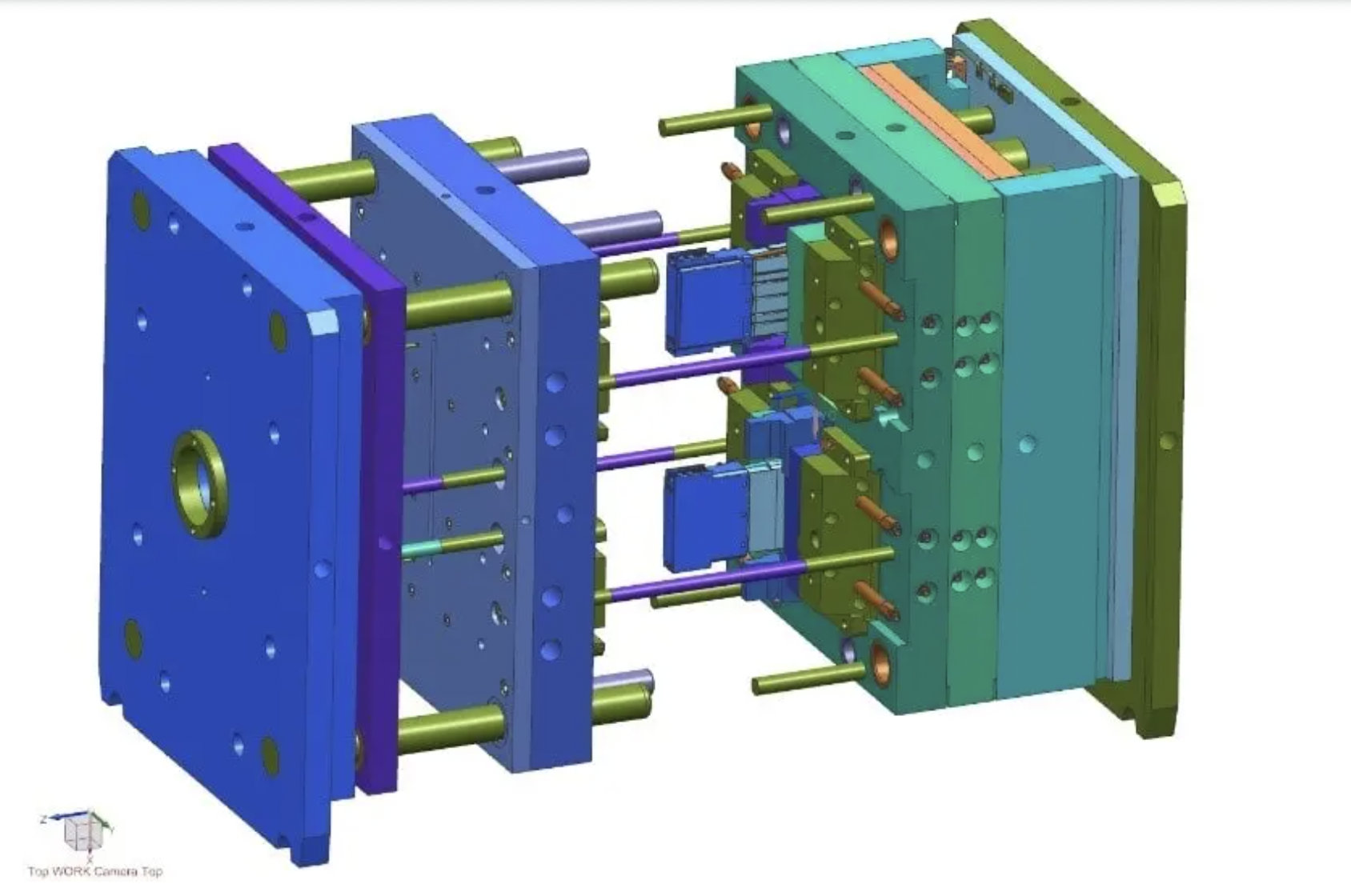

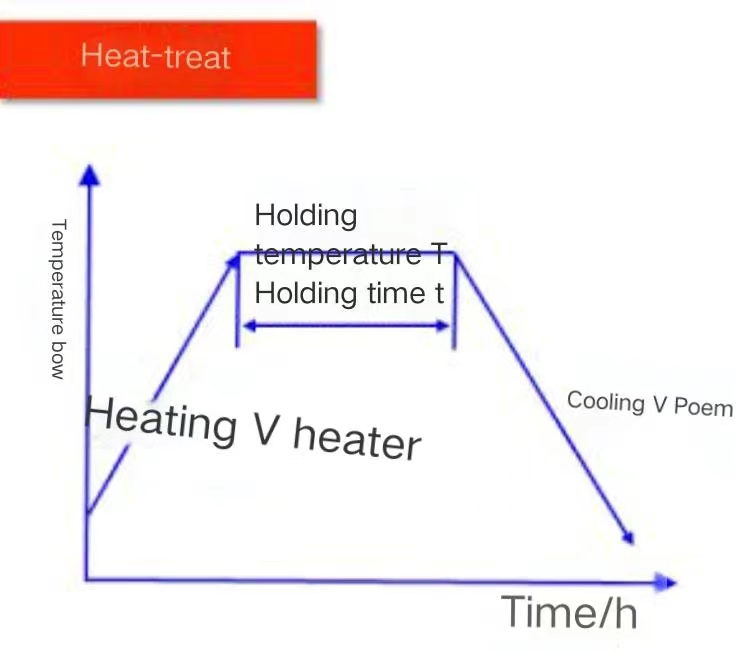

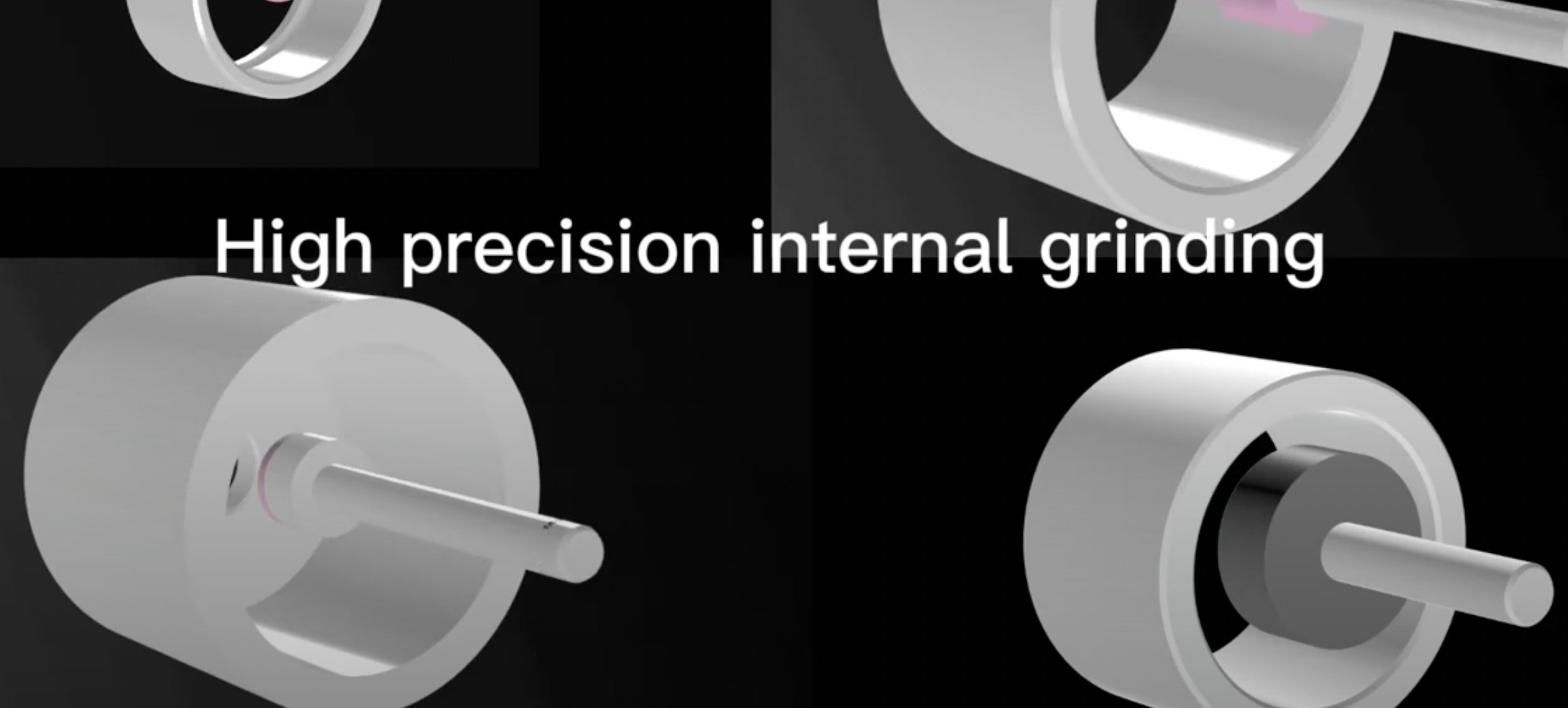

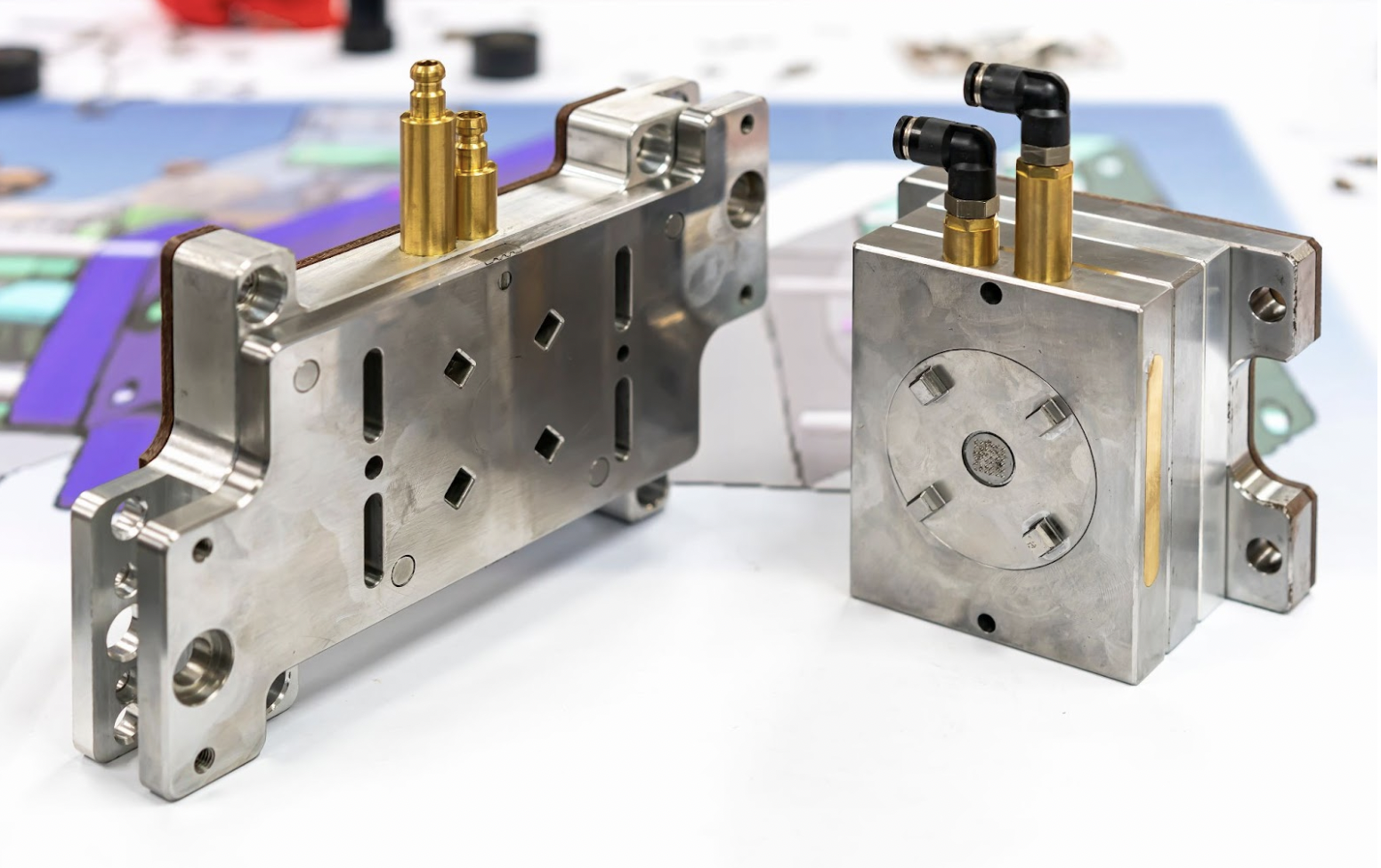

At Opro Tech , we thrive on overcoming challenges to deliver excellence. Recently, we faced the intricate task of #CNCmachining #POMC material with a delicate thickness of 0.7mm. Deformation concerns...